Looking at the undercollar of a jacket will reveal a lot about the quality of the jacket. A more in depth explanation will follow for the serious geeks, but the reader’s digest version is this;

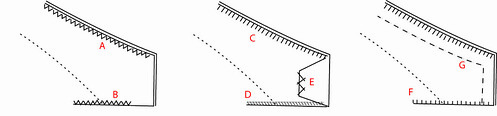

There are several ways to make a collar, some better than others. At the top end it is sometimes difficult to distinguish between hand-made, machine made, etc. but the one generalization that can be made is that if you see zig-zag stitching along the edges of the collar (figures A & B), it is not the best type of construction construction. This is an example of a more economical way of producing a collar and is either just felt or fused felt but it is certainly not felt with linen padded to it as you would find in top-of-the-line garments.

Let me clarify one thing though- it is not the stitch itself which is necessarily better or worse; the type of stitch used is an indicator of the way in which the collar is assembled and attached to the jacket, and THAT is where there are a lot of differing levels of quality.

Here is a diagram of the types of stitches I will refer to in this post.

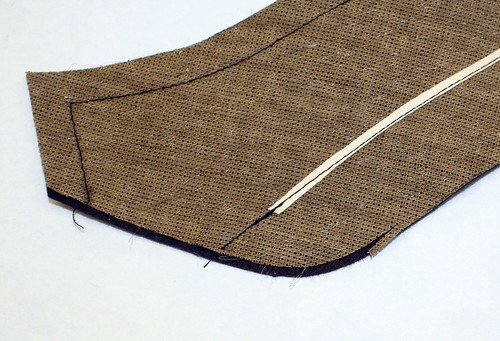

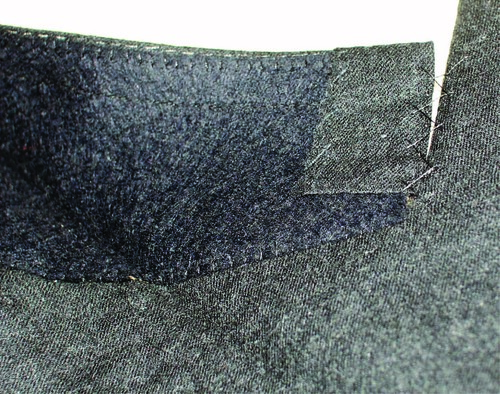

Here is a collar which has been machine padded. Many people (myself included) feel that there is no added benefit to padding by hand over machine- but that is the subject of another post. The stitching and tape is used to stabilize the roll line; some tailors will draw this tape, keeping it close to the neck, all depending on how they construct their collar. The stitching seen at G is a very good indicator that the collar has linen canvas padded to it- the padding at the edges will be slit open so that the seam allowances of the top collar can be inserted BETWEEN the felt and the canvas, making a nice flat collar without visible impressions. Also notice that I have begun to trim away the canvas at the edge- this is necessary to prevent the canvas from showing through and is quite time-consuming. Aside from the fact that padded collar canvas costs three times what just plain felt does, it is this trimming operation which is the impetus behind factories using only felt.

In the photo below you see a collar made by Samulesohn- it is very difficult to make out the stitches at the edges of the collar but it is clear that they are not zig-zag stitches. The outer edges at C were done by machine, but one that closely resembles a hand-stitch.

The AMF machine which makes a stitch which is virtually indistinguishable from a hand stitch is pretty hard to find these days, so some factories are using a blindstitch-type machine to fell the collar. Same general procedure but different stitch like the one shown at D. Mechanically it is the same as the AMF stitch or hand-felling, but is unattractive. That said, you don’t usually go around with your collar up so who cares?

The little turn-under shown at E has been hand-finished and is the traditional way of finishing a collar, giving a smoother, flatter finish.

3 comments:

your last comment about buttonholes, are you talking about a machine or hand sewn?

Hand-sewn buttonholes are rarely attractive from the wrong side, unless they were double-worked like Oxxford does (or has done- I'm not sure if they still do).

Hey Jeff, I realize I'm about 4 years later on this but I'm taking up a bit of tailoring and have decided to go back through all of your archive. You probably have my all time favorite blog. Can you speak to whether or not you feel collar construction in diagram CDE or FG has more releative merits? it sounds like you favor padded collars. Any specific reasons?

Post a Comment