Il parait que j'ai quelques lecteurs Français- et bien, si les choses ne sont pas très claires, dites-le moi et je me tâcherai de faire un peu de traduction.

Bonne année!

So here is some of the progress so far.

As promised, I pulled the pad stitching from half the collar and redid that half by hand; the stand is pretty heavily padded, the fall is more lightly padded and the ends were curled under as I worked to keep the corners tight to the chest. After breaking the collar, there is no noticeable difference in shaping or shape retention, though that may change, particularly after it's been worn so we'll have to keep checking back on this one. The side which looks bare is the one done by machine- it is done with a fine, clear monofilament thread which is nearly invisible.

Going back to the business of felling, here you see that the facing seam has been sewn to the canvas; this can also be done by blindstitch machine. As we work across the garment we are sewing everything together, in place, so that nothing moves once it's been (shudder) steamed or had its first chemical bath at the dry cleaners. On more economical garments, this seam may be glued in place, which will come apart after a few cleanings; some garments whose lining has been "bagged" will not be tacked at all.

I talked about Chris Despos' method of balancing the patterns on the back; this is the result for this check. Normally when I draft the back, the result would have the lines evenly balanced (mirrored) at the neck so that the collar matches but very close together at the hem. Chris' idea is to balance the pattern at the hem, as shown- this requires more shaping with the iron to get a good shape to the back, but I like the result shown below. I recently worked with a navy cloth with a very bold white windowpane; it would have been much nicer done with this method. My one snag is that I like to be able to keep a person's pattern on file once a garment is finished so that there is less fitting the next time I cut a garment; with this method a new back must be drafted for every cloth if it is a stripe or a check, requiring different amounts of shaping and fitting. One of those techniques I'll keep tucked up my sleeve for when I have very distinct fabric designs.

To further drive points about felling and steaming home, let's consider this side vent (look closely, it's there); the back hem is folded up and the back underlay is folded under- the side body seam allowance is folded back and the hem is folded up. This is a lot of folding- eight layers of cloth, not to mention the lining. A lot of stuff to fall out of shape as a result of humidity and cleaning, which is why we fell everything in place, so it keeps this nice flat appearance. But let's consider that many manufactured garments are not felled so that the lining can be bagged; let's also consider what happens to a pant crease when it is steamed- it relaxes unfolds itself. So someone who takes their jiffy steamer to the back to get rid of wrinkles is also relaxing those 4 creases used to create the vent and since they are not felled in place they just open up. I can guarantee you that the vent will not sit flat any more.

The most intriguing for last.

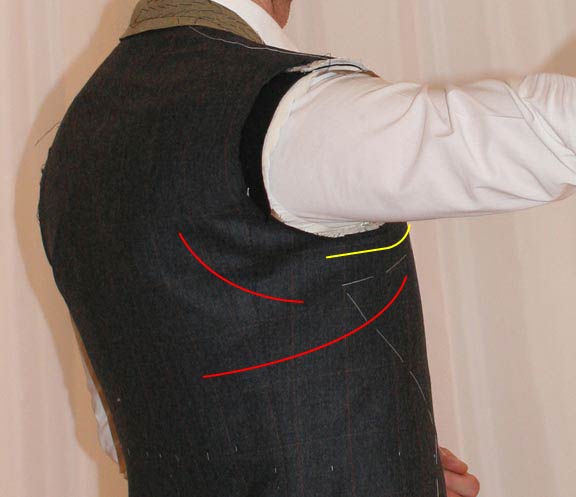

The proponents of hand sewing the sleeve talk about elasticity and looking at the chain stitch versus tape in the armhole looked promising in this regard so I decided to observe what areas of the garment come under the most strain during movement and was surprised at what I saw. When we reach forward we feel the back of the armhole straining; this area is mostly bias and so I figured if the chain stitch and hand sewing could provide support and elasticity it would be far superior to a lock stitch. But what I saw (and is difficult to see in the photograph) is that the back armhole was not even touching my body at all; the forward motion of the arm was dragging on the front of the armhole, causing the area shown in yellow to pull, and that the garment was pulling on my blades but mostly along the latissimus dorsi. The bias area received no tension at all, and the area under strain is on the straight grain so there would be not much give at all. The front of the armhole and a large part of the underarm are tacked into the canvas which negates any benefit of elasticity so I am starting to have big doubts about this. I also wonder if those who equate hand-sewn seams with elasticity consider that bathing suits and T shirts are sewn by machine and yet are elastic so if elasticity is really so key then surely a machine dedicated to those operations requiring it would have been invented. There are still enough big guns who advocate hand-sewn sleeves so I am still not ruling it out but it's starting to look like marketing hype to me.

As I was preparing the armholes a contextual distinction came up; there are two sides of the tailoring coin- one is the independent tailor shop, the other the factory. Why is this important? In the context of a tailor shop, which may have only a lockstitch (plain) machine and maybe a serger and blind-stitch machine, there are a great deal of operations which must be done by hand to be done correctly. In a factory there may be machines which can do the same operation to the same level of quality but in a fraction of the time. So to say a certain operation is better by hand than by machine can be true if in the context of a tailor shop, but not true if in a factory. But it goes beyond that.

I am preparing the armholes to eventually have sleeves set in. Certain parts of the armhole are susceptible to stretching, and others must be kept short in order to create shape; the lower part of the front armhole is held short to help build the chest and to keep the sleeve tight to the body. The back armhole is held short to clean up the blade area. The majority of makers use a small cotton tape in the armhole to prevent stretching and to hold the extra length, like this

The black cotton tape serves to stabilize once this area has been shaped, and so that the sleeve setting is cleaner.

The makers who attach their sleeves by hand normally do not use this tape which "locks" the armhole, but make a chain stitch by hand, which holds the armhole, draws it short where needed, but is still elastic. There is an amount of give and recovery which you don't get when the tape is used.

But then it occurred to me that we have machines which make this exact stitch and can perform this same function; in the case of the tailor shop, it is true that doing this by hand provides elasticity, but in the case of Kiton or Oxxford, they would be able to afford such a machine that performs the same job. If you are going to insert your sleeve by hand in order to preserve the elasticity in the seam, you would not use tape but use a chainstitch. It then occurred to me that it might then be confusing or difficult to explain to a consumer that one is done by hand, the other machine, but that one machine method is identical to the hand method whereas another machine method is far lesser. It then becomes a blog subject :) Maybe it's just better to do by hand in order to preserve the cachet of the "hand sewn armhole" since the consumer perception is that the hand sewn would necessarily be better.

Whatever the case, I am leaning favorably toward the chain-stitch rather than tape right now, and could eliminate the tape in my factory in favor of a chain stitch method. In this case, an industrial duplication of a traditional, hand-sewn application. To be continued......

I'd like to wish everyone happy holidays, and a healthy and prosperous new year!

This period is a little anti-climactic for me- after the rush to get everyone's suits finished for the holidays, coupled with the Christmas shopping and parties and general craziness, we close for the next ten days and I don't know what to do with myself. I'm not very good at doing nothing and I've gone through my last pile of books. So the experiment will continue.

I have made garments entirely by hand before, and one which were partly done by machine because I don't think that it's worth doing certain things by hand, like the collar padding and the sleeve hanging. However I've never been able to really properly compare the two so my opinions are untested- really, I should make two suits out of the same cloth and same trimmings but made using the different techniques. Ok, I may be a clothing geek but I'm not quite that hardcore; there is a limit to what I will do in the interest of sartorial investigation. Instead I'll do a half-and-half.

I found and end of flannel, a nice charcoal with a camel-coloured windowpane which unfortunately does not photograph all that well- it's a lot nicer in person. I'm going to do my back the way Chris Despos does and see how that turns out. I'm going to see if I can match the sleeve to the back like in the Paul Smith garment pictured elsewhere on this blog. I'm going to take some pre-padded collar melton and undo half of the padding and redo it by hand to see if there's a difference between the two. I'm going to sew one shoulder seam by hand and the other by machine. I'm going to set one sleeve by machine and one sleeve by hand.

I will either end up with a garment which looks distinctly different one side from the other and will thus be unwearable but it's an end so it doesn't matter- all I have lost is my time; however, I will have learned something in the process. Or I will have a wearable garment which may be more comfortable on one side but is visually indistinct from the other, in which case I will have a wearable suit and will have learned something in the process. Either way I will have learned something and either proved or disproved some of my theories, at least to me. So it's win-win.

Happy holidays!

I showed how to spot the different ways of hemming a lining and explained why it would be better to do by hand or by the special felling machine, since allowances inside are felled in place. But what does that really mean?

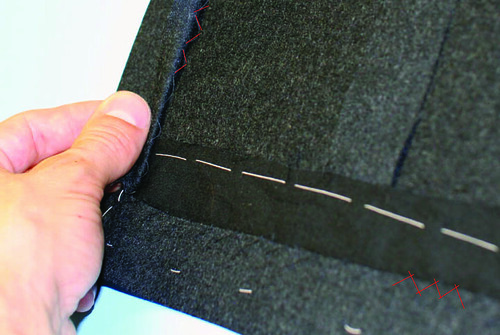

Have you ever got your trousers back from the cleaner and there was a phantom crease near the new crease in your trouser? A result of wear, humidity and the cleaning process, the trouser loses some of its crease. If the presser at the dry cleaner is not extremely careful, he will not make his new crease in exactly the same place as the old one. The same can apply to hems and vents- during construction they are usually basted in place so when they are creased, they are creased exactly where we want them to be. If, as a result of wear, humidity or cleaning the hems fall or the vent puffs, it can be difficult to get the crease back in the same place as the old one. One of the goals of tailored clothing is for the garment to maintain its original shape for its useful life; in order to prevent hems from sagging and vents puffing and lining and facings falling out of shape, we tack as much as possible in place, which is permanent. Looking at the photo of the back panel (which has side vents) I am turning up the vent underlay to show how this underlay has been invisibly felled in place using a zig-zag-shaped stitch. Along the bottom, you can see (though not all that clearly) that the hem has been cross-stitched to the cotton interlining, which has, in turn, been stitched to the garment fabric using the same type of stitch as the vent underlay. This can also be done using special blind-stitching machines. This felling prevents the lining from being sewn in using a conventional lock-stitch machine, which is why it must be felled using the felling machine or by hand, as illustrated in the post on hems. So when you see a hem sewn by lockstitch machine (the bright blue lining in that post), you are seeing the manner of closing the lining but you also know for certain that the allowances have not been felled in place, only tacked at the seams, unless glue was used to hold things up, which itself can wear out after wearing and cleaning; it is also almost guaranteed that the facing has been glued in place rather than felled with a blindstitch.

I don't usually get nervous while I'm working but I'm drafting a gentleman's overcoat this morning and he is flying in for a skeleton fitting later this week so I need to rush a little. Lovely pure cashmere from Cerutti- I'll need about 4 yards at $500 a yard. That's $2000. Not something one wants to goof up.