There have been a lot of questions lately which I promise to get to at some point, but I'm on the road these days so it's a bit nuts.

So in the meantime, some buttonholes.

Remember this?

I made this jacket last year, just before leaving Canada. Ellen Degeneres saw it and liked it so Drew had one made for her (not by me- my contacts within that camp don't know where to find me these days) and will be presenting it to her on Monday's show. I saw a post on facebook which is how I found out about this coat-

Fans of the bold, colourful cloth typical of many Italian merchants (especially Isaia) will love Ariston Napoli. This latest piece- a blue and brown check- comes from them, and is surprisingly robust for an Italian cloth. They are represented in the U.S. by Kemp and Hewitt.

This time I mean it.

So I had some scraps. And maybe a bit too much coffee.

I don't like most of what Thom Browne does, but I understand why he does it. And all those guys who you see in the Sartorialist's Pitti photos. It's not that we're trying to get photographed (ok maybe some are). It's just that those of us who are surrounded by grey and navy suits day in, and day out, who deal with them all day at work, who already have a closet full of grey and navy suits and when it is time to make something new for this season the thought of making yet another grey or navy suit, well, just yyyaaaaaawwwwwwnnnnnn. It takes something a little more unusual to excite me these days. I mean, how many professional musicians walk around with the Four Seasons or Pachelbel's canon in their iPods? They're more likely to have Arvo Part or Meredith Monk, or something most non-musicians won't get because I-IV-V-I has become as mind-numbing to them as the charcoal suit is to me.

Or maybe I've just had too much coffee.

I bought these four pieces of Vendon by Holland and Sherry back in February and I am just now getting the last of them finished. It's a great cloth- a robust weave which is normally quite dry but this has a roundness to it and even a nice soft finish. If memory serves, there a few other colors; I may go and see if there are any left to pick from. At the same time I am going to have a browse through the Ariston bunches- a Neapolitan merchant who makes just the sort of horseblanket and FU checks that I love for sportsjackets (some of the louder cloths that Isaia and Oxxford use are from Ariston).

You'll notice that the shirt sleeves are far too long- the shirt is new and has only been washed once so I expect they will shrink some more. I had three of them made from a very opaque white cotton from Thomas Mason, I believe (I don't remember the name of it, but Joe from MyTailor tells me bought a whole lot of it) and I have actually had people stop me in the street to ask about my shirt so if you are in the market for white shirts and go see Mytailor, ask Joe about- he'll know what you're talking about.

In other news, I closed on the condo last week so I'll be moving again, hopefully for the last time in a long while!

When I was growing up we had a book in the house that I considered the sewing bible. If ever I was was stumped on a particular application I would pull out the old Vogue Sewing Book and it would have clear, well-illustrated instructions on how to insert an invisible zipper or chain-weighted hems. While informative, it was not terribly inspiring.

Back in 1995, New York's Metropolitan Museum of Art staged a stunning exhibition on Haute Couture. The beautiful catalog of that exhibit joined the Vogue Sewing Book as one of my go-to books, this one providing the source of inspiration which the other was lacking.

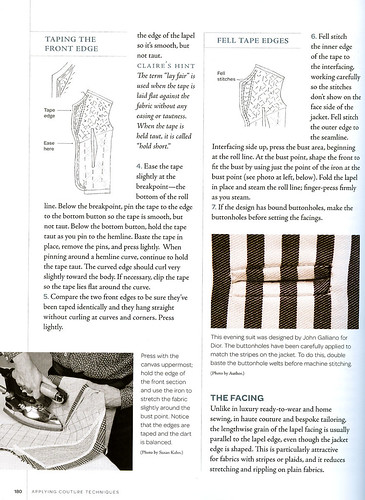

I don't do much sewing other than tailoring these days, but when I do, I have been using a new reference, Claire Shaeffer's Couture Sewing Techniques. Not only does her book provide the type of technical detail that I found in the old Vogue Book, but stunning examples of real-life couture garments and the application of those techniques, as well as a chapter on the history of haute couture, including the maniacal attention to detail, like matching the stripes on bound buttonholes, for example.

Claire recently sent me a copy of her newly revised and updated Couture Sewing Techniques, which includes a new chapter on designing with special fabrics, and tons of fantastic and inspiring photos taken from her countless visits to ateliers, museums, and from her own extensive collection of couture garments. If you don't already have a copy, I can highly recommend it, and even if you do, you may want to consider the upgrade. As I flip through the pages I am already planning my niece's wardrobe. Is four years old too young to be wearing couture?

Mmm, no.

This has been some time in the making but it's in the final push to finish it. The film maker has made an appeal for donations to help her finish. If you liked the trailer and want to see the rest of it completed, you can go here to make a donation. I did.

MEN OF THE CLOTH IndieGoGo Video from Vicki Vasilopoulos on Vimeo.

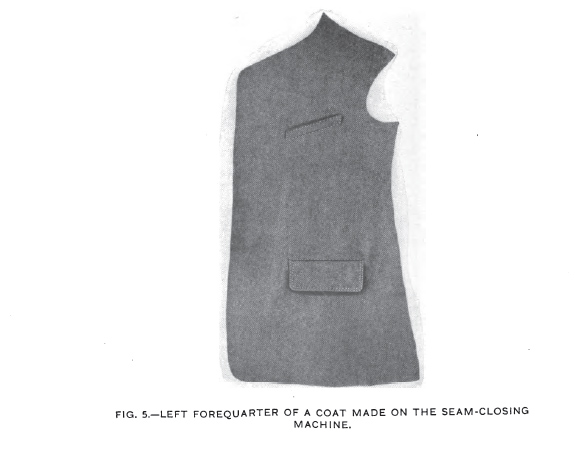

The internet has a way of expanding the English language and ever since discovering the tailored clothing forums I have also encountered a term that I had never heard used outside of the internet, and that was "quarters". As in, a way of describing the shape of the front of the coat. Whereas in tailoring circles, or the ones I have always frequented, anyway, have generally referred to a "straight front" or a "cutaway front", the internet usage has people referring to "open quarters" and "closed quarters". Which sounds more like an architectural term to me, but whatever. I never understood where the term might have originated, suspecting one of the forum stars may have coined it and it become an iTailor meme.

Well, I think I know where it comes from now.

An illustration from the book I referenced in my last post, showing the "forequarter" of the coat, something more commonly called the forepart, particularly since coats have generally been cut in six pieces since the 1930s, not four. So while it is not completely without precedent to refer to the "quarters" of a coat, it's something you might more readily find at "ye olde taylor shoppe". But then, the iGentry seem to fond of anachronisms, and so it is perhaps appropriate.

A few book reviews to do.

The first will appeal only to the super-geeks like myself. Published in 1916, The Men's Factory-Made Clothing Industry is a report on the cost of producing men's clothing produced by the U.S. Department of Commerce, and can be found on Google Books.

Buried within a lot of dry financial statistics is an interesting history of ready-to-wear clothing in the U.S., as well as some very interesting descriptions of the manufacturing process, some of the machines already in use at that time, and some startling passages such as the following:

"The imports of clothing into the United States are almost negligible and are generally English overcoats, novelty garments like the Balmacaan, and golfing and motoring clothes. No sack suits are imported.

...

English ready-made clothing is not comparable with the American. The English hand tailoring is poor, except in the finest custom work. Very conservative styles of men's clothing are worn in England; the models do not change from one season to another as they do in this country. High-salaried designers [ahem] are employed by the larger clothing factories in the United States, who are constantly introducing attractive styles.

...

American people believe not only that the styles of clothing for men that are originated in the United States are superior to those that come from other countries, but also that the workmanship of the domestic product is superior to the workmanship on ready-made clothing produced in foreign countries. This belief accounts, in a measure, for the tremendous increase in the production of factory-made clothing in the United States during the last 20 years.

While the manufacture of ready-made clothing is one of the large industries in the United States, this industry is of comparatively small importance in other countries. The completeness of the factory equipment, the thoroughness of the factory organization, and the efficiency of the working force, which are noticeable in many establishments for making men's clothing in this country, are not even approached in other countries. Nearly all the ready-made clothing manufactured in Europe is of low-grade, cheap varieties, and is almost invariably manufactured in small factories, in shops, or in the homes of the workers."

I knew that the method of manufacturing by breaking down the process into minute operations had originated in the U.S. and had been exported to Europe, but was a bit startled by the assertions about the level of quality, mainly because the reverse is often true today. In retrospect, however, it makes perfect sense. But taking it into a larger context, we can trace the progression of the source of quality goods from the U.S., then to Italy who has held the crown since Brioni started to push the "Made in Italy" brand back in the fifties, and now it's moving to China. Many people still associate Chinese-made product with inferior quality, just as Japanese electronics were once considered junk, but those of us who have actually visited facilities in China know that they are not far off from the potential of eclipsing Italy in terms of production of quality garments.

I hope I'm still around in 50 years so I can witness for myself how the manufacturing landscape will have evolved.

Nothing to do with clothing for once.

MSNBC’s Dylan Ratigan recently went on an emotional rant worthy of Keith Olberman and the avalanche of response prompted a follow-up in which he expresses the collective rage of the American people toward Washington and the economy. He encourages the people to take to Twitter and Facebook and the blogosphere to express the fact that we are Mad as Hell and that we demand change.

While I agree with the idea that social networking-driven grassroots movements are a new and interesting force in politics and society, I am, personally, a little tired of all the anger and instead offer a bit of constructive musing.

I am currently contemplating the purchase of a home (and am lucky enough to be able to get the credit to do it) but the state of the economy gives me pause; while I am hesitating I realize that it is this very lack of confidence that is one of the greatest threats to the current state of affairs. I am no economist so I may be way off base on this, but it seems to me that in a consumer-driven economy (I believe that the U.S. is 70% consumer-driven), if people aren’t spending money then business aren’t selling things and thus do not need to employ people in order to create and sell these things. My hesitation is perpetuating our economic problems. Of course, I think it is a very good thing that people are scaling back on extravagant spending and living within their means rather than within the means of their Mastercards, but I also think that it is very obvious that we can’t wait around for the turkeys in Washington to fix this mess- they won’t- and that we the people can do something simply by having a bit of nerve, and instead of hiding all of our cash under the mattress, that we responsibly spread some of it around (leave the credit card at home, please). That is, after what drives the economy and the jobs machine and maybe we can fix the economy ourselves, or at least give it a hearty push.

So it may be a stretch to suggest that buying a home despite worries about the stock market, or even just a buying pair of shoes can be seen as an act of patriotism, but in my perhaps twisted world view, that is exactly what it is at this moment in time.

So excuse me while I call my realtor, and then we can get back to the subject of clothing.

EDIT- The very day I wrote this post I got an email from my realtor- the place I am interested in has been on the market forever but that very day they got an offer on it and if I am interested I need to move NOW. So I am looking at a potential bidding war. The irony.

A storm blew through town last night which took down some pretty big trees, and with them, the power. Mine finally came back on this morning but the office is still closed so I glanced over at "the pile"; various garments that have been collecting over the last few months waiting to be chopped up, photographed, and analyzed- maybe today I can dig in a bit and get some blogging done. I've been pretty busy so I'm a bit behind in it, but I realize that I think I'm also running out of interesting things to say; it's getting to the point where there's not so much that's new and interesting to show you- we've seen it all before. (Right at that point I got a message notification about a comment from a reader which read "NEW POSTS PLEASE!!!" Talk about timing)

Well, one things we haven't seen, and which people have asked for several times, is an image of one of the dissection victims on a form or a body, to get an idea of the cut or silhouette. Until now the dimensions of most of the garments were such that I wouldn't have been able to, even if I wanted, and I have to caution that it's not a good idea to put a garment which was cut for one specific body onto another because you don't get an accurate picture, but this one was cut for someone very close to my build, though quite a bit taller than I, judging by the sleeve length. So, for a change, we can have a look at the cut of a garment.

It's a proper 3-button garment with a decent amount of waist and a bit of flare to the skirt. The chest feels fairly firm, but this is not surprising as G&H have a history of military tailoring.

I had heard that G&H use blindstitch machines to pad their lapels so I expected to see that; instead, they were done by hand. There is a liberal sprinkling of fusible in various parts of the garments, but nothing we haven't seen already on other garments from Savile Row so I won't go over them again.

What was a bit surprising was that the chest was padded by zig-zag machine, in a similar fashion to the Saint Andrews garment I cut up, but with a smaller, tighter stitch, which is what gives the firmness to the chest. It would take too long to unpick the whole thing to show you what's inside, but I did just enough to know that the entire chest (the size of the felt) is one big piece of haircloth, with another smaller one in the shoulder. Again, no surprises there.

Another thing I found interesting was that the seam joining the side body to the front is shoved way back, making a very narrow side body. This probably makes the shaping of the waist easier- I will have to try it out. I don't know if you can make the seams out in the photo, but FWIW,

As for the rest, it's all stuff that we would expect to see, and have seen, on other Savile Row garments (newer readers are invited to peruse the archives), so I will blame my writer's block on the clothing.

I'm sure that's a first.

Remember this stuff?

I normally prefer smooth finishes or at least a fine, tight weave; coarser weaves seem, rightly or not, somewhat outmoded and more difficult to work with because they fray easily and don't always take shaping as well. When I first came across this cloth from Holland and Sherry I was a bit skeptical, but it came highly recommended by someone I trust, and had been favorably compared to Minnis' Fresco by others (another cloth I am tepid toward) so I decided to give it a go.

I'm glad I did.

I struggled a bit with the fullness in the sleeves on the first coat I cut and I wasn't happy with the finished results so I ripped out the sleeves, cut them down, and set them back in shirt-sleeve style and was very happy with it so I cut another coat with this kind of shoulder expression in mind. I have to say that I'm really pleased with the way this cloth is making up- it is sturdy and can take a bit of a beating (good for travel) but is soft and fluid enough and breathes fairly well.

Sometimes it's good to step outside of your comfort zone.

When it's done I'll try to get better shot with better lighting because this doesn't do the coat justice. (See a tutorial on lighting clothing shots here which was helpfully submitted by its author. I will try not take that as a way of saying "dude- your photos suck" LOL)

Franca has shared her latest DIY project (or rather, her husband's). Chalk sharpeners are not the easiest things to find and are certainly not cheap when you do so here is her version (if there is demand, perhaps we could encourage her husband to offer "bespoke" chalk sharpeners on Etsy :)

the box € 2.50

4 packs of 10 blades € 1.00 each total € 4

various bolts € 1

Total € 7.50!!

Grazie, Franca!

I think the Asolsa Lucida, or glossy buttonhole (the example above being from a Tom Ford garment), originated in the Abruzzi region of Italy as it is most commonly seen on garments made in this area. It is also very common in Paris, where it is known as the boutonnière Milanaise, though likely for the brand of gimp that was commonly used and not the city; it is worth noting that most of the grand tailoring houses of Paris also trace their lineage back to Italy. The gimp itself, which is a key element of the buttonhole, I believe is now only available from Guterman and is known as Agreman; I will be in Italy in June and will dig around to see if there are any other manufacturers still producing the stuff and will report back if I find any (and if anybody else will be at Pitti and feels like meeting up for a drink, drop me a line).

A while back, Matthew was kind enough to share a method he learned at Cifonelli for making these buttonholes, his with a purl underneath the gimp. The ones made by what I shall call the Abruzzi method, for want of a better term, do not have this purl under the gimp and the stitch is made differently- I will attempt to explain it now that I have figured it out.

In addition to the previously mentioned gimp (and do not be tempted to use what most other companies sell as gimp but is really intended for machine-made buttonholes) you will need some fine silk twist- to get a really smooth, glossy finish, a thread finer than the 40 size typically used now, and much finer than the U size that some still use, is needed, and unlike ordinary buttonholes, the twist should not be waxed.

Because this buttonholes is more fragile than the regular knotted one, it is typically only seen on the lapel, not on the lower buttonholes.

I start by running two rows of machine stitching to hold everything in place while I overcast the edges- it might also be a good idea to stitch even closer to the cut line than I have done and instead of ripping them after overcasting, just work the buttonhole over the stitching. A very narrow bite is required and this helps keep things from shifting, but also means that cloth that frays very easily is unsuitable.

The mechanics of the stitch are actually quite simple but may take some getting used to if you have done lots of traditional buttonholes.

Working from the underside, pass the needle up through the hole- I find it easiest to poke the eye end through to avoid catching anything with the sharp end. I come up through the hole and then work the twist under the gimp, but for the sake of clarity I have shown the needle passing directly under the gimp. Do whatever is easiest for you.

Come up and over the gimp, then insert the needle a millimeter from the edge- tight, close stitching is the key to a smooth appearance. You want the gimp to sit right on top of the stitch to conceal it, and by tightly spacing the stitches you will completely encase the gimp.

I've pushed everything to one side so you can get an idea of how the stitches are forming.

Pinch the gimp before working around the end of it the continue down the other side.

The completed buttonhole. You can see some of the stitches poking through beyond the gimp where my bite was a little too wide- I need to practice some more (and really have to think more seriously about a macro lens...)

And thanks again to Matthew and Franca for inspiring this post.

EDIT- In response to a question, I made a few phone calls. In the U.S. Agreman gimp can be bought from B. Black and Sons (1-800-433-1546), Oshman Brothers (1-212-226-7448) and Ely Yawitz (1-800-325-7915) It is not listed on their websites so you have to call and ask for it.

In the U.K. it can be bought from Richard James Weldon 44 208 300 7878. I know there is at least one store in Paris which stocks it (ask for milanaise), though the name of it now escapes me. It is also available all over Italy (ask for vergolina).

Custom shirtmaker CEGO's Carl Goldberg shared a few garments from his father's wardrobe with us, one of which is a DB jacket (pants long lost) made by Gilbert Feruch, some time in the seventies, I think.

I gather he was something of a futurist, and the V&A museum has a Nehru suit that he made on display. Other than that, I know practically nothing about him. What I find most interesting about this garment is that had he removed the label, I would have sworn it was a Smalto, the garment we recently looked at. There are so many details which are virtually identical that it is impossible that the two were not somehow linked at some point in their careers. I won't speculate on that link but if someone has more information I would love to hear it.

While I was surprised to have seen a two-piece top collar on a piece of bespoke work, here is another one.

The buttonholes are fairly good, though they may have seen better days, particularly the Milanaise which looks to have had a flower or two through it.

This is how buttons should be sewn on.

Like the Smalto, the pocket jets have been stitched by hand. The breast welt and its facing have also been constructed by hand, and sewn through the chest piece.

While the interior finishing on many of the coats we have looked at has seemed like an afterthought, Feruch is clearly making a statement here.

Again, pocket jets done by hand

The lining has been inserted by hand and stitched up in an identical fashion to the Smalto.

Even this diagonal tack is identical.

While the Smalto had wiggan in the vents, this one has silesia, but cut and inserted identically to the Smalto

The real differentiator between the two is that the Smalto had been padstitched by machine, and this one has been done by hand.

Note how the direction of the stitching was reversed to help with the peak of the lapel

The collar has been padded by hand with a piece of silesia on each end.

The chest and shoulder pad have also been done by hand, and the same kind of cut and reversal of the direction of the grain as I found in the Smalto.

The final detail was that the facings had been drawn on entirely by hand, while the Smalto (like so many others) had been done by machine. And for those who still care, the sleeve was set by machine and the shoulder seam sewn by machine. Absolutely everything else on this coat had been done by hand so clearly they were not looking to save time or cut corners- if they thought there was any benefit to doing these steps by hand they would have been done by hand. But they were not.

Other than the few steps which had been done by machine on the Smalto coat, steps which may have come later to help bring costs down as the Smalto is much more recent than the Feruch, these two coats are so close that they could have been made in the very same workshop.

Intriguing, no? Thoughts, anyone?

And thank you, Carl.