Wednesday, November 28, 2012

Wednesday, September 19, 2012

The Rake on the Asola Lucida

Shameless plug.

This month's issue of The Rake has an article I wrote on the "Boutonnière Milanaise", or the Asola Lucida.

Just a heads-up for those among us who can't get enough buttonhole porn.

Monday, September 17, 2012

Indochino- How did my garment turn out?

OK let’s get to it. This is going to be a long one. And while most of this is specific to my experience with Indochino, a lot of the pointers could apply to any kind of MTM experience so may be worth a read to anybody who is thinking about getting a suit made. I’ll address some of the construction details in another post.

There have been a number of questions and comments here and elsewhere that I will try to address, but if I miss something, please let me know in the comments section.

First, I want to address expectations. Several people have said that they like what I make for myself better. Well, duh. If what I make for myself is not a million times better than an inexpensive MTM garment I should immediately quit what I am doing and become an accountant instead. You can’t compare a hand-made bespoke garment with MTM.

Which brings up another point.

If you have spent any amount of time browsing the online clothing fora, you should probably know by now that even bespoke clothing, being the result of expert craftsmanship and several fittings, which by all accounts should be the pinnacle of perfection in fit, is still subject to imperfections. I can count on one hand the number of online posters who own what I consider to be impeccably-fitting garments, and 99 times out of 100 (or more) they are the result of an ongoing collaboration between client and cutter. The first attempt is almost never even close to perfect- any true customer of bespoke clothing will tell you this. So I think people need to moderate their expectations when it comes to made-to-measure clothing, especially in the first attempt, and most particularly with less conventional formats such as this one. This is not to excuse egregious errors which may occur, but to put a little perspective on things.

Generally, however, people seem to agree that Indochino did pretty well on this suit, compared to some of the other examples floating around the internet, and questions have arisen to why this may be. I certainly didn’t give them much guidance. So what made the difference?

Well, first off, I am not a believer in making clothing from measurements alone. Three people with the exact same chest circumference can be shaped completely differently- the very erect guy with flat back and prominent chest, the stooped old man with a dowager’s hump and flat chest, and your average Joe. How on earth is a chest circumference supposed to capture this? Then there is the matter of personal preference. To the client’s skin measurement we always add what is known as “wearing ease”. This is not a compression tshirt, it is a suit- it must be bigger than your own measurement to some degree. And it is the degree which trips people up. Standard ease would be between four and six inches more than the body measurement- for example, if your chest measures 40”, the coat chest should generally be between 44” and 46”, depending on how you like to wear your clothes. One guy will find 4” too big, however, and the next will find it much too tight. How do you account for this?

TRY-ON GARMENTS.

When I was fitted, my measurements indicated two possible sizes to try on. I tried on three. This is probably the most important part of any MTM process- find the garment that is closest to a good fit, especially in the shoulders, and work from there.

And this, kids, is the moment where you need to step up and pay attention. This is the point where you need to communicate to your fitter if the length, the button stance, the general fullness, everything is right for you. If not, now is your chance to say so; your fitter is not a mind-reader. Is the sleeve a bit too snug? Is it perfect? Is it too big? Say so now. Have the fitter explain exactly what changes they intend to make to the garment you currently have on. They may think the waist needs to be cinched a bit, but you feel that it’s fine. Say so.

That being said, how does one manage when one does not have access to a trunk show and you have no option other than to submit measurements online? The remake policy is probably the best (only?) way around this. Self-measuring is a crap-shoot at best, but with a good alterations and remake policy it takes much of the risk out. My one caveat is that customers should not try to micro-manage the remakes. A lot of what I see going on online makes me cringe, when the customer tries to get too specific or too technical. Send them pictures and explain generally what you don’t like- “the shoulders are too wide”, for example. What you interpret to be too much padding may have nothing at all to do with padding so if you ask them to remove padding with the expectation that the expression will change, you will fail. If, given your general description of the issues and some good photos (dump the iPhone, please) the technicians at the factory can’t figure out what needs to be done from that, then you telling them to “reshape the sleeve head and crown to fit the armhole” is certainly not going to get you anything except possibly frustrated, especially since the Chinese-speaking technicians may have no idea what the internet-fueled jargon you may be using actually means. Unless you are a trained garment technician, or you play one on the internet, do not try to get overly technical.

Another element which may have contributed to the success of my garment was that I had one of their in-house fitters who flew in from Vancouver- many of the others are hired temps which get a few hours of training in fitting. Some have more experience than others, which may suit the general population who doesn’t know better, but if you are reading this blog then you are probably more attuned to fit and should be working with one of their more experienced people. I found my fitter’s story compelling- he was initially a customer of Indochino who was so impressed by the experience that he went to work for them. That says a lot about his level of enthusiasm and interest which probably went a long way toward making my garment a success.

I also think that the majority of what we see posted on StyleForum is not representative of the real world. I think many of the posters can be fit into one of three categories;

1) Look on my new bespoke Rubinacci, ye small-timers, and despair!

2) ZOMG look at the new Kiton jacket I just scored on ebay!!1!!

3) I just got a new suit in the mail and I don’t think it fits but I can’t articulate why

It’s very likely that Indochino has a lot of satisfied customers who can’t be bothered to post photos of themselves on the internet, I and if the success rate of a company could be judged based solely on what we see posted on the clothing fora, Anderson and Sheppard would have gone out of business a very long time ago.

Now on to the nitty-gritty.

The shirt is not bad for a first attempt, but considering their emphasis on fitted clothing, I find the back especially blousy. Darts would go a long way to contouring the fit and should probably be added as a matter of course (Heikal, are you reading this?). The collar and sleeve length are correct, and those are probably the most critical points.

My only gripe about the styling of the trouser is that I would prefer a narrower bottom with such a narrow knee- this borders on looking flared, and I would also shorten a trouser this narrow- there should really be almost no break at all, if any. It’s pretty typical that the back hits the calf when you taper so aggressively to the knee, though in general they could pick this up a bit. The fit of the seat is very good, though I gave them some help. I have what we call a “prominent seat”; the default for most trousers is to have one dart above each pocket and there is no way that a trouser will fit my seat with only one- two are required. They add a second in certain instances (it was not entirely clear when- it seemed like only the large sizes got them) but I insisted that a second would be necessary in my case. They said they would try, and they did. The pockets sit flat and do not gape; there is a bit of pulling in the thigh but that is pretty typical of a trouser that is so close-fitting in the thigh. Customers are advised to pay particular attention to the fit of the trouser during the fitting as they are quite slim.

The vest seems blocky, but I haven’t cinched the belt, which would help. I did it on purpose because the majority of vests on the market have loose, blousy backs which really need to be cinched a lot, and I hate that. The back of this vest is actually very well done, quibbles about the position of the neckline aside; it could also be a bit closer to the body, but then I would not have room to eat. If it were a bit longer and the points more elongated than horizontal, it would look a lot slimmer than it currently does, but would be too long in proportion to the jacket. I may ask Foo to work his magic on the picture so you can see what I mean. But in general, a better –than-average fit.

Several people have commented about the length of the jacket being too short, stance too high and lapels too narrow. Were this a classically-styled garment they would have a point, but this is not. It’s a fashion-forward garment. I tried on some Isaia DBs in Milan and the hem of the jacket was about even with the hem of the sleeve, so if one is to judge by what’s going on in the market, it’s maybe even a tiny bit too long. I think that’s getting into dangerous territory for a DB and think that the details of this garment, for what they are trying to achieve, are actually correct.

The fit of the shoulders is good, however I don’t think that they are set up to capture low shoulders- in any case, they seemed to have missed mine. I would have sloped them a bit more as well. Other than that, the fit of the front is quite good, and I like the sleeve length.

The back is pretty good, with two exceptions. They need to work on their sleeve pattern (to be fair, the back of the sleeve is the Achilles heel for most clothing pattern designers) and the seat of the coat is much too small, causing the vents to gape badly. This also seems to be a recurring theme so they may want to look at their base patterns.

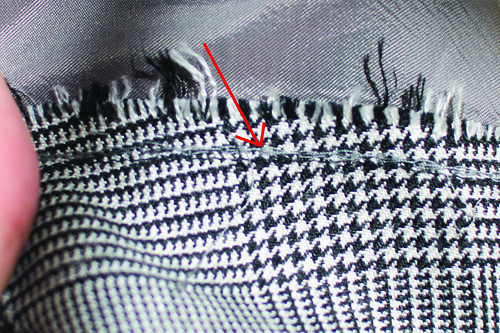

On the subject of sleeves, they didn’t match the plaid on the front. This is a must, in my books, though certain Savile Row cutters wouldn’t agree- I have seen a lot of SR garments which weren’t matched either. I’d be willing to give them a freebie lesson on matching plaids if this is anything other than a mistake on their part (Heikal?).

So on the whole, I consider this experiment fairly successful; other people have had different results, though. If you’re in the San Francisco area and want to have a look, or even try it out for yourself, the Traveling Tailor is there this week, from the 18th to the 23rd. It’s worth a look just to see their setup. You can book an appointment here.

Saturday, September 15, 2012

Indochino- first impressions

The suit and shirt came earlier than promised but I was busy so I let it hang for a few days. Since I know how to press a suit, it was conceivable that I might have improved it a bit by giving it a good press so I shot it as it came out of the box. If I have time, I'll give it a press and reshoot, to see if that makes much of a difference in the fit.

I'll get into more detail about it early next week, but here are some first impressions. On the whole, I'm pleasantly surprised for the most part.

During the fitting process I let them do their thing. I wanted to get the "Indochino experience" so I didn't guide them, with one exception. Readers will have to keep something in mind; when you go to Indochino you are getting a skinny, fashion-forward suit like you might find on the pages of GQ or Details. This is not bargain-basement Brioni, and if you are looking for classic proportions according to "whnay's good taste" thread then you are looking in the wrong place. However I think it is good to have a point of view and to be very direct about it; there is too much half-baked clothing on the market which tries to be everything to everybody and thus fails in most things.

Thursday, September 13, 2012

Eating Out

I was shopping one day with a friend who had come in from Milan for a visit. He is also in the trade so we enjoy "doing the stores" together, to check out what everybody else is doing. We stopped into L'Uomo, in Montreal, which Alan Flusser called Canada's finest menswear store. The salespeople there love their product, are incredibly knowledgeable about it, and love to talk about it, especially with those who exhibit an appreciation for what they are selling.

That day they had me try on a sportcoat. A Very. Expensive. Sportcoat. The fit was absolutely spot on, the construction was immaculate, and some of the details kind of fascinating. I was a little bit in love. Okay, maybe a lot.

"Buy it", my friend said.

"You are out of your mind", I replied. "This thing costs a bloody fortune and I could make it myself. I can't spend this kind of money on something I could make myself!"

"Bello," he sighed impatiently, "do you think Jamie Oliver never eats out? And when he does, do you think he eats at McDonald's? Buy the damn thing."

Check, and mate.

I couldn't think of an argument. So I bought it. And he was right, in a way; sometimes it's good to try out what other people are doing because it makes you think of things you wouldn't have thought of otherwise. I learned a lot from that coat so I wrote the expense off, in my own mind, to my own education.

Fast forward a few years.

When I was in Spain, this spring, I got to chatting with the designer from Boglioli. He really liked a jacket I was wearing, the one I had made from the Ariston cloth that I bought from Kemp and Hewitt. He especially liked the way I got my collar to fit so we chatted a bit about it. He was making a technical presentation and had some garments with him so I tried some of them on. They are fantastic garments- really soft and lightweight, they feel like you have nothing on. A bit like Kiton, but whereas Kiton looks like a rumpled mess, these actually looked pretty clean. They do a huge amount of research and testing on treatments like washes and proprietary finishes so their garment is pretty unique on the market, but very expensive, due to all the testing. I complimented him on the garments and made some offhand remark about buying one if I had several thousand dollars I didn't know what to do with. Ha.

A few months ago he got in touch with me to let me know that he would be visiting New York in September, and that it would be great if we could get together. We exchanged a few details, then he came up with an idea. Knowing I loved their product, he offered to make me one of their coats in exchange for one like the one I was wearing in Spain. We could meet in New York and exchange garments. I thought this was a great idea. We'll get a chance to turn them inside out and talk about how we did them. I love this kind of exchange, both of ideas and of garments.

So I ordered some more cloth and am making him a sportcoat. I can't wait to see how mine turned out- I will no doubt be posting some photos when I get it.

Thursday, September 6, 2012

Indochino- a box came

They promised delivery for September the 8th- it actually arrived September the 4th.

Anyone who has had items shipped from abroad knows about nasty surprise brokerage fees and duties and stuff. There's none of that- they deliver the box and that's it.

So far, so good.

I'm going out of town for the weekend so I don't know if I'll be able to shoot anything useful before then, but I will try. Meanwhile, if Brad is still reading, if you got your suit, please get in touch with me- I'd like to know how yours turned out as well.

Wednesday, September 5, 2012

What's a $4,000 suit worth?

I am occasionally contacted about my services as a bespoke tailor and I have to try to explain that, while it is something I very much enjoy doing, I only do it for the fun of it, and not as a business. Why? You just can't make decent money doing it.

The NY times ran a short piece about tailoring and economies of scale.

Which is a better explanation of why the RTW industry is my bread and butter, and why the only time I take on a new commission is because there's something I really want to make- purely for the pleasure of doing it, and not for the money.

Saturday, August 18, 2012

Indochino, or, How to Sell Clothing to Generation Smartphone

This blog has been, first and foremost, about studying tailored clothing, often analyzing other people’s methods so that readers and I can learn something. Up until now the focus has been solely on the construction of tailored garments; for the first time, I wanted to study somebody else’s method of selling tailored garments.

The ready-made tailored clothing industry is almost 150 years old; many of the companies still producing in the United States themselves are well over the century mark, and most of us are very prone to the “but we’ve always done it this way” disease. And it really is a disease. I happen to think that London’s west-end tailors fell to this a long time ago- they felt so confident in the fact that they were the world leaders in quality tailored clothing, as they were for a very long time, that they never noticed that many other schools of tailoring worked so hard at improving themselves and in many cases they ended up surpassing the product being sold on Savile Row. The men’s made-to-measure industry in the US may be nearing that moment right now.

My last post mentioned Indochino, one of the numerous upstart MTM clothing companies. When Indochino first hit my radar a few years ago, I wasn’t overly impressed. Aside from my deeply-held skepticism about internet-based MTM, and self-measuring in particular, there were some glaring quality issues at the time. When I encountered them at our convention in Spain this spring, however, my ears started to perk up. They were addressing many of my initial concerns in some very fresh ways, ways that the rest of us, if we were smart, should learn from. When I heard they would be hosting on of their new pop-up stores at Chicago’s Union Station this week, I was very curious to go see for myself.

Clothing geeks will be familiar with the name of Frederick Scholte, the famous London tailor who, in the beginning of the twentieth century, turned the industry on its ear when he developed a new silhouette called the Drape Cut, or the London Blade. It was pretty radical at the time, and by the 1930s became hugely popular with English and Hollywood royalty. There are many stories of manufacturing executives approaching Scholte, posing as customers, wanting to have one of his famous suits made so that they could study them and copy them in their new ready-made factories. Scholte was sharp, and he was also a curmudgeon; he could sniff them out pretty quickly, and they would be promptly tossed out of his shop. The twenty-something co-founders of Indochino are far more accommodating- when I told them that I wanted to take a look at their operation to see what I could learn from them, instead of tossing me out, they offered to make me a suit. Classy.

What sets Indochino apart is their approach to the shopping experience. Men generally hate to shop, and they especially hate to shop for clothes. There is one shopping experience, however, which manages to lure the male customer, and hang on to him, and these guys seem to know that; from the moment I walked in to their “shop”, I felt like I was at the Apple store.

The shop occupied the great hall of Union Station, a gorgeous space to do an event like this. A space this big and this grand could easily dwarf a clothing trunk show, but the strength of the visuals, the fixtures, and the branding on every possible surface managed to hold its own, and occupied the space rather than being overwhelmed by it. Everything, from the coffee cups to the water bottles and cookies are branded with the sort of attention to detail that reminds one of Steve Jobs.

You are met, upon arrival, by a host who will whip out their iPod touch to plug in a few basic details about you, such as name and email address. Al l in the Indochino App, of course. The generation of customer that they are targeting knows all about iPods and iPads and apps, so he feels immediately comfortable with the type of interface. This is not my father’s clothing store, it says.

You are then handed off to a fit specialist who will measure you, and input those measurements into your file which they have brought up in their own iPod. In fact, at each step of the way, each specialist will have access to the information that the previous specialist has entered. Armed with your basic measurements, the fitter will select a size of garment for you to try on to determine your preferences in fit. Instead of the industry-standard sizing, they have come up with their own. These are two very important points. First, what one customer may think is far too tight, the next might think is far too loose. This is one of the challenges of any kind of e-commerce model where clothing is concerned; Indochino has chosen to address this with their pop-up stores so you can try stuff on, then when you want to order repeats, the process can be entirely internet-driven. Second, I know first-hand about people’s reaction to sizing- “what do you mean I’m a 44? I’ve never been a 44! I’ve been a 40 all my life!” “ Well, sir, have a look at the tape- it says 44- would you like me to pull it hard enough to get a reading of 40?” “That’s impossible. Your tape is wrong.” Well, customer in question has never been a size 8 and has no basis of reference, and no reason to protest. Very clever.

Alterations are punched into the iPad and you’re handed off to a stylist who will guide your choices.

This is usually the part where the customer’s eyes glaze over and you lose him. He’s now off on some other planet and has no idea about, and even less inclination to make the sort of decisions about the styling of his suit. Show him a box of swatches and he starts to fidget; expect him to be able to visualize what a 4x6 rectangle of cloth will look like made up in a suit and you’ve just about pushed him over the edge.

Indochino’s fixtures have full lengths of cloth which you can feel, play with, and even remove from the fixture to drape over your shoulder to get an idea of what the cloth will look like on you, with your own coloring and complexion. It makes every bit of sense. The ranges are organized on separate fixtures, and for those who are still challenged, photos of the cloth made up as a suit are attached. It’s about as dummy-proof as you can get.

Linings are also rigged like the fabric choices.

Details about cuffs, collars, hems, waistband finishings, are all displayed in well-labeled cases.

And if you’re still not sure, just about every possible variation has been rigged so you can see it on a finished garment.

Of course, there may be options available that they don’t have on hand. So there is a bank of (Apple, of course) computers where you can browse their website and see the entire range of options.

When your choices have all been made, they are read back to you to confirm, and you’re off to the cash. Except there is nothing so pedestrian as a regular check-out counter; your credit card is swiped through the little square reader sticking out the bottom of an iPod and an email is immediately dispatched to your address with a receipt, a confirmation, and a delivery date.

When your garment is delivered to your home three weeks later, Indochino provides a $75 credit toward any alterations which may be required and which can be performed by a local tailor. They also have a rep come back to town a month after their traveling tailor show to do follow-ups for alterations. Of course, if you are unhappy, they will also remake the garment for you.

The results of the shopping experience itself are the result of approaching the business from an entirely new perspective. The downside to that, as they are discovering, is that the learning curve in tailored clothing is steep. Very steep. That said, the quality is vastly improved since the last time I looked closely at their garments, and if their efforts toward developing the quality of the garment match what they have done with the quality of experience, I have every reason to believe they will succeed. What they need now, in my opinion, is a partner or a buyer with clothing industry experience to give them the technical support and industry experience that they are currently lacking. If I were the CEO of a major manufacturing outfit, I would be very interested in what these guys are doing.

Meanwhile, check back in three weeks to see how my suit turned out.

Monday, May 7, 2012

IACDE in Santiago de Compostela

I just got back from my weekend in Spain and it was a real eye-opener. The men’s tailored clothing industry had better wake up fast and see that the rest of the industry is adapting to a different consumer, one that was being called “generation smartphone” and if we keep on just doing things “the way we have always done them” we will get our butts kicked.

Some of the highlights of the trip, other than Zara’s mind-blowing facilities (and Paco, I haven’t had a chance to read that article yet) were presentations by Lodovico Zandegu, the technical designer at Boglioli, and Kyle Vucko, CEO of Indochino. Lodovico discussed the special treatments that their clothing gets, which includes garment dyeing, washing, and other processes. A huge amount of testing goes into their product development so that was really interesting. Kyle’s very fresh approach to custom clothing was also exciting- they are approaching clothing from a completely new perspective and once they get some of their kinks worked out I think they will be a company to watch.

The thing I wanted to bring to readers, however, was a new initiative of the IACDE. The International Association of Clothing Designers and Executives has been around for just over 100 years and brings together the top professionals of the industry in a yearly world convention. This convention includes technical presentations and factory visits, and can be a valuable source of information as well as a great networking opportunity.

This year we voted to authorize funds to start an outreach/internship program. The Executive Committee (of which I am a member) has to work out the details, but essentially our aim will be to find young (or not so young) talent and support their participation in these conventions (pay for travel etc.) and to arrange possible workshops, masterclasses, and factory visits during the year. We also discussed internships with member companies. This will be a global initiative so we hope to support young talent from all parts of the world. Candidates will be required to submit a CV, a brief essay, and probably photos and/or sketches of their work, and a selection will be made from these submissions. Once we get all the details of the program and the requirements worked out, they will be posted to the IACDE website (and, of course, here) but I wanted to give readers a heads-up so interested candidates could start thinking about submissions.

You can also send me your email address to be included on a mailing list once we get it all sorted out.

Friday, April 20, 2012

IACDE World Convention

This year's world convention of the International Association of Clothing Designers and Executives will be in Santiago de Compostela, Spain, on the 4th and 5th of May. The theme of this convention is fast fashion, and we will be visiting the design center of one of the world's leaders in fast fashion, Zara/Inditex. Also on the program are presentations by-

Jesus Echevarria- Zara, Inditex corporate presentation

Lodovico Zandegu- Boglioli,Speed in luxury

Dr. Karl Hendrik Magnus- McKinsey & Company, Strategic Perspectives on the Future of Fast Fashion

Joachim Hensch- Hugo Boss, the Future of Fast Fashion – opening of the 2012 IACDE world convention

Dr. Andreas Seidl- Assyst GmbH, 3d-Modeling and Fast virtual Prototyping

Roland Schuler- ESPRIT, Strategic Product development as Precondition to Accelerate Fashion Flow

Kyle Vucko- Indochino Inc, Online custom clothing and e-retailing

Ed Gribbin- Alvanon Inc.,Technology leaps for the Future of Fast Fashion

Jean-Luc Auverdin, Frederic Piriou- Chargeurs Interlining, Interlining Solutions for Fast Fashion

Simone Visani, Ulrich Scherbel- Freudenberg Interlining, Fast Fashion – differentiation through innovation

The program and registration information can be found here. I sit on the executive committee of the IACDE so if anyone is interested in find out out more about it, feel free to contact me.

Monday, April 16, 2012

Asola lucida- some instructions

For Mike, who says he still doesn't get it.

I hope this helps.

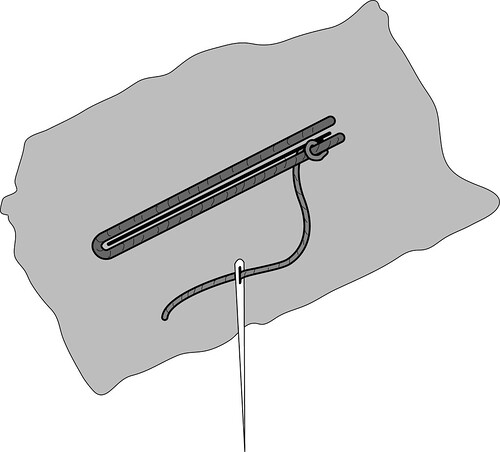

(Sorry that the illustrations are rotated from the photos, but maybe this will actually help)

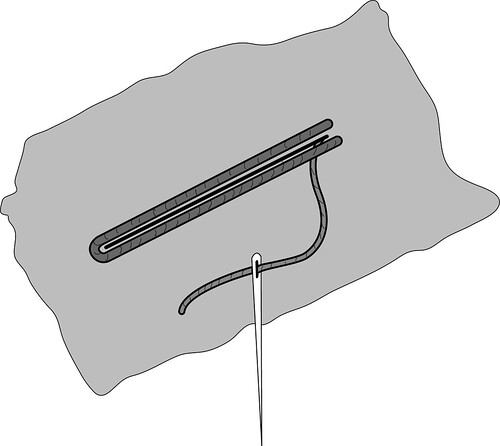

1.

Cut through the cloth, overcast, and lay a length of gimp. Do not wax the silk twist. Unlike regular buttonholes which start from the top, the twist must be anchored on the bottom of the hole (on the wrong side).

Feed the needle through the slit, then underneath the gimp.

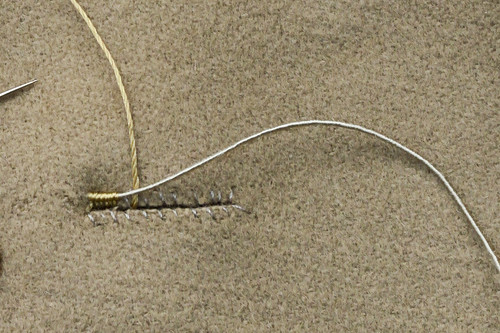

2.

Wrapping around the gimp, insert the needle underneath the gimp, about 1/16" away from the slit edge.

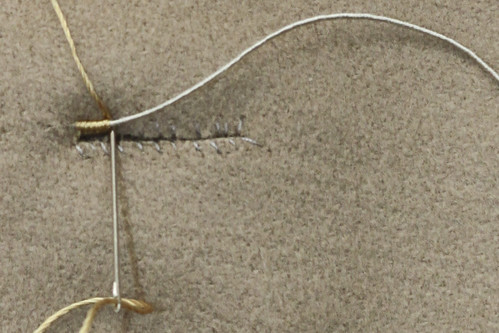

3. Pull tight.

4. Repeat by feeding the needle up through the slit. When taking the next stitch, insert the needle exactly next to the previous stitch, and do not leave any space between the two. You may need to nudge the stitch with your thumb to pack them in tight.

Monday, March 5, 2012

Vent finishing

There were a number of questions about the vent finishing on the Ralph Lauren Purple Label garment, so here is a look at it again, with a comparison to an engineered method.

The traditional method of finishing the vents has the lining seam follow the shape of the side body, with a hockey-stick-shaped step at the top of the vent.

In this case, it has been (exquisitely) finished by hand, however it is possible to do this by machine. So this, in itself, is not a sure indication of the level of construction.

The engineered method pushes the side seam over so that it meets the top of the vent in one straight line, like this one.

When we flip the underlay up, we can see the most telling thing. The engineered vent's lining will continue in a straight line down the vent. This method can be done entirely by machine, no hand finishing is required.

The traditional method has an underlay of lining underneath the cloth underlay- notice how the lining extends closer to the edge of the folded vent.

This kind of application must be slashed, basted, and finished by hand so it's a pretty good sign. I like this method because the lining seam can be tacked to the cloth seam to prevent shifting- the engineered method can't be tacked because the lining seam is offset from the shell seam.

Joanne asked if I knew of any online instructions for vent finishing and unfortunately, I don't.

Monday, February 13, 2012

Ralph Lauren Purple Label

Every once in a while a nice surprise comes along.

I was contacted by Lance at Virtual Clothes Horse to see if I would be interested in a garment he had. A Ralph Lauren Purple Label sportcoat made by Raffaele Caruso, which, by itself, was intriguing. What was most interesting was that this one was recent, new, and had all its tags. Usually I have no idea of the age of a garment, and more often than not, it’s pretty old and not reflective of current workmanship. In this case, it’s safe to say that it’s pretty current. It was a MTM garment that was unclaimed by the customer and whose size was such that Lance felt he would have a hard time moving it so he ended up donating it to us. Thanks Lance!

Before we start cutting, a reality check.

Ouch.

The garment is made of cashmere and silk, a blend that is normally so flimsy and unstable that it’s a real headache to sew. But this is a fantastic 2x2 construction that is robust and shows no sign of the distortion in the grain or any of the seam slippage that is so typical of this blend. Certainly a contributing factor in the price.

Readers are, by now, aware of my buttonhole fetish and so will not be surprised to know that one of the things I most eagerly anticipated were what promised to be sensationally hand-made buttonholes. To my only partial dismay, there were none. Not one. Which actually makes a lot of sense. Not only are the sleeves basted in preparation for final adjustments before cutting the buttonholes, but the omission on the front and lapel leaves the possibility of making certain adjustments to the fit of the front which would have been impossible had the buttonholes been cut. Whether this was a special request by a very particular salesperson or client, or whether this is the usual practice for Purple Label MTM service is unclear, but at almost $5,000 one has every right to expect a properly-fitting garment so every precaution should be taken.

Inside the pocket we find this attractive pouch holding the buttons and, of course, a spool of silk buttonhole twist.

The twist is Seta Bozzolo Reale by Cucirini Tre Stelle which I mentioned in previous posts. It is distributed in the U.S. by Gilbreath Threads, who can be contacted at 800-247-2396 or by clicking here.

Ok, so I lied. There was one buttonhole.

The envelope flap on the inside pocket had a buttonhole embroidered by hand.

Along the facing edge we see some pick stitching. I often see ebay descriptions of garments referencing “tons of handwork”, usually describing this stitching, among other things.

I hate to break it to you, but this was not done by hand. Two types of machine exist to make this kind of imitation hand stitch. This stitch was done with a machine that makes a looping stitch on the wrong side,

Because the underside is unattractive, it’s usually used only on parts whose wrong side will be concealed, like the facing, and sometimes the trouser pockets and fly. Never on the coat edges.

Before anyone gets their knickers in a twist over “deceptive practices”, even the Kiton garments I examined had used this exact type of machine stitch.

The other type of machine is made by Conti Complett. The underside of this stitch, unlike the other type of machine, is neat and resembles the hand stitch it is meant to duplicate. The downside of this machine is that it is slow and very expensive.

The label was stitched on using a Complett machine; notice how very uniform the stitching is on the underside- only a machine will be this precise.

Now have a look at the underside of the flap- nothing at all like the label, so it is most likely that the edge stitching was actually done by hand. Very few RTW makers do this by hand anymore because the machine generally does a good job.

Of interest to some will be the old-school vent finishing which is rarely seen on ready-made garments-

However the bottoms have been finished by machine, a step some makers at this level still do by hand.

The front canvas is very generous, and rather than using haircloth in the chest, a very good quality wrapped hair has been substituted. This is similar to what we saw in the Saint Andrews garment and gives a softer feel to the chest.

Notice how the edges of the chest piece are taped to prevent the hair from poking through.

No surprises to find a semi-bias piece of haircloth in the shoulder

What is somewhat surprising is the size of the pad- this is the thickest pad I have seen in RTW for a long time. Mr. Lauren is known to appreciate a more imposing shoulder than some of his American colleagues.

The collar is seamed at center back- again, very old-school

In fact, the entire collar has been constructed and attached by hand, including the gorge. Very nice.

Portions of the edge tape have been felled by hand.

There was something about the edges of the coat that caught my attention but I couldn’t quite put my finger on it. Upon (much) closer inspection I found that the entire facing had been drawn on by hand. In other words, where most (including most bespoke tailors) would join the facing to the coat along the front edge by machine, this facing has been carefully basted in place, wrong side to wrong side, with the edges turned under and then slip-stitched by hand all along the edges, and they have done a magnificent job of it. The Brioni dinner jacket is the only other RTW garment I have seen which featured this technique, and only few bespoke pieces were done this way. I was intrigued so I made a few inquiries.

Paul Farrington, the technical designer at Hickey Freeman, visited the Caruso factory recently. Paul spent his early years at Chester Barrie, including a stint at D’Avenza. He told me that the system used at Caruso was brought first from Chester Barrie to Saint Andrews in the late sixties, and then to Caruso by a technician named Frank Vita. To augment the old-school tailoring is a decidedly new-school tech system which has bar-code driven PCs at every station so operators can reference specs, components, and sewing instructions. This kind of system allows for minute adjustments and customization the likes of which most of us in the trade can only dream. Paul did say that the regular production gets machine-sewn facings- only certain garments are done by hand, which makes sense since I am not aware of their house label selling for such astronomical prices.

This garment definitely ranks up there with some of the best of the recent ready-made garments I have examined- I’m going to have to try to get my hands on a trouser to see how those are made as they promise to be just as interesting as this coat.