A busy post box this week. A parcel came yesterday and today a notice that the post office is holding one; I'm hoping it's the A&S I've been waiting for. In the meantime, I give you Saint Andrews. Thanks to HRoi for getting it here so quickly!

Also known as Saint Andrews, Sartoria Santandrea produces garments for a number of better doors but is not so well known in North America except perhaps by fans of Ralph Lauren's Purple Label, as Santandrea produces some of their tailored clothing (perhaps all? at one point Cantarelli also did some).

There's not a lot to learn from this garment but for the sake of those who are trying themselves who makes a better garment, let's have a look at some of the details.

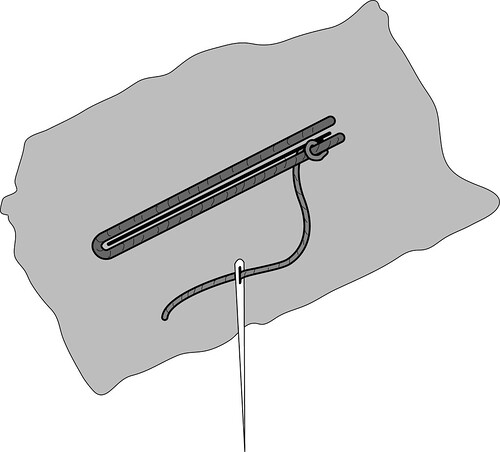

The buttonholes are very nice (naturally, they are done by hand) and the top buttonhole (the one that is meant to be buttoned, not the boutonniere) has been worked on both sides.

The back of the buttonhole

Something interesting.

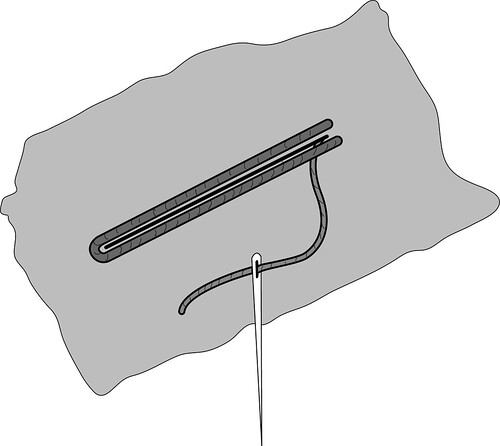

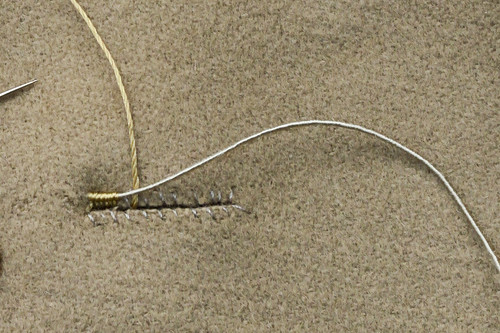

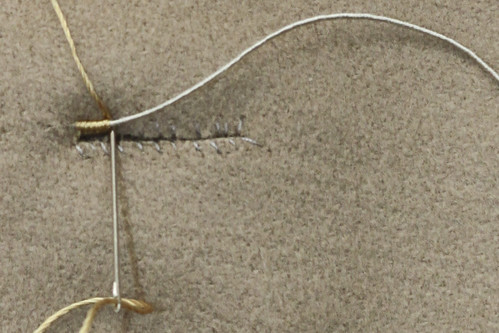

If you go to their site and go to "lavorazione", then "asole" you see someone making a buttonhole by hand. If you look closely you can see that the buttonhole has been whip stitched before making it (which is typical), but the stitches are very close together, which raised a flag. I have mentioned before that certain well-known Neapolitan makers make their buttonholes by machine with fine thread first then work them again by hand. A friend of mine who worked for a company which does it told me about this, saying it was much easier to get consistency in the cutting of the hole, and because it was all stitched up first, which is stronger than a hand stitch. It made the buttonholes much easier to make. We were talking about this because I was looking for gimp alternatives and he told me that by doing this, no gimp is necessary. As open-minded as I like to think I am about machines, this was one line I was not willing to cross.

Anyway, back to Santandrea. Having seen that photo on their site I got curious so I ripped one of the (admittedly beautiful) buttonholes and found one little strand of silk twist, which is usually not nearly enough to gimp a buttonhole. Under my big magnifying glass, though, I could just make out an extremely fine thread and a distinct machine stitch (a tiny zig-zag which maybe you can make out in the photo). They had been worked and cut by machine before being remade by hand over top. My mind still rebels, but it does make sense for the longevity (no slippage in loose cloth, which is sometimes a problem) and it does make a nice buttonhole. Something to think about......

Anyway, back to the garment.

Shamholes done by hand on the sleeve

However the inside of the sleeve has been finished for functional buttonholes.

The underside of the flap shows that the pick stitching was done by hand in a slightly heavier silk thread than the English use- the English use a very fine thread so that it is very discreet whereas the Italians like it to be a little more showy. But not much. The little prick marks about 1/4" form the edge are from an edge baster- instead os basting edges by hand which is actually a little uneven and can produce a slightly wobbly looking edge, we use a single-thread chainstitch machine to baste the edges during production. The chainstitch is very easy to remove before final pressing.

The neck has all been finished by hand and the top collar has been drawn on completely by hand.

The collar itself has been constructed by hand (though padded by machine) note that there is no turnback at the end of the collar.

The breast pocket is the curved "barchetta" type and is done by hand, the same way I learned to do them, as opposed to the way I recently learned to do them thanks to Huntsman and Jukes.

Notice there is no exposed seam allowance inside the breast pocket and it has been felled by hand, not by machine.

A moderate amount of wadding in the sleeve head and a moderate pad- more than Poole, about the same as Huntsman, a little less than Brioni.

The canvas holds no surprises, though it has been made with a zig-zag machine as opposed to the twin-needle jumpstitch machine that I prefer.

Removing the felt, we can see that instead of haircloth, which is firm and expensive, there is another piece of the same type of canvas as is used on the front. It's been machine padded to within an inch of its life, which makes it a bit firmer but still softer than haircloth, so I'm not going to bother ripping the stitches to open it up.

Instead, I hold it up to a strong light to see what's inside. There is a haircloth shoulder reinforcement and you can see the series of vees, or cuts, to give the shoulder some shape.

Finally, a look at the shoulder seam, which is machine-sewn and stayed with a piece of bias-cut silesia. If you read the Poole dissection you will remember that Poole stayed the shoulder with a straight-cut piece of lining which had no give- this silesia will stabilize the shoulder but still give. I will soon be conducting some experiments concerning elasticity in the shoulder so stay tuned......

In response to Jordan's questions and comments about the curved barchetta pocket, I agree, when well done it can be quite nice, though sometimes it is overdone and looks affected. It is the default shape in southern Italy and is catching on in the North too, so I doubt any of them would think it would clash with a straight-cut lower pocket, so long as it was subtle.

The pocket welt itself is curved, not straight cut and bent into shape, and therein lies a bit of the difficulty in making the pocket (and why some curve it a lot more in order to show off a bit) so it's not an issue where stripes and plaids are concerned.